If you haven't already done so, make sure to check out this months issue (April 2013) of Architectural Design (AD) titled Computation Works: The Building of Algorithmic Thought. Edited by Xavier De Kestelier and Brady Peters, this issue focuses on emerging themes in computational design practices, showcasing built and soon-to-be-built projects and provides a state of the art look at current computational design techniques.

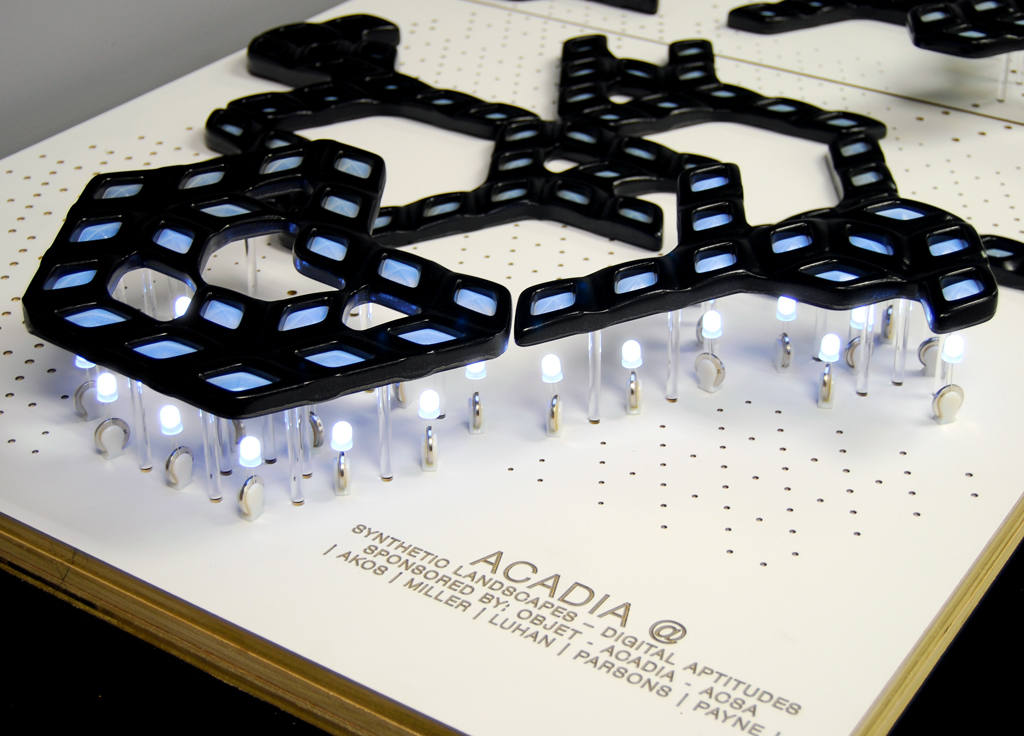

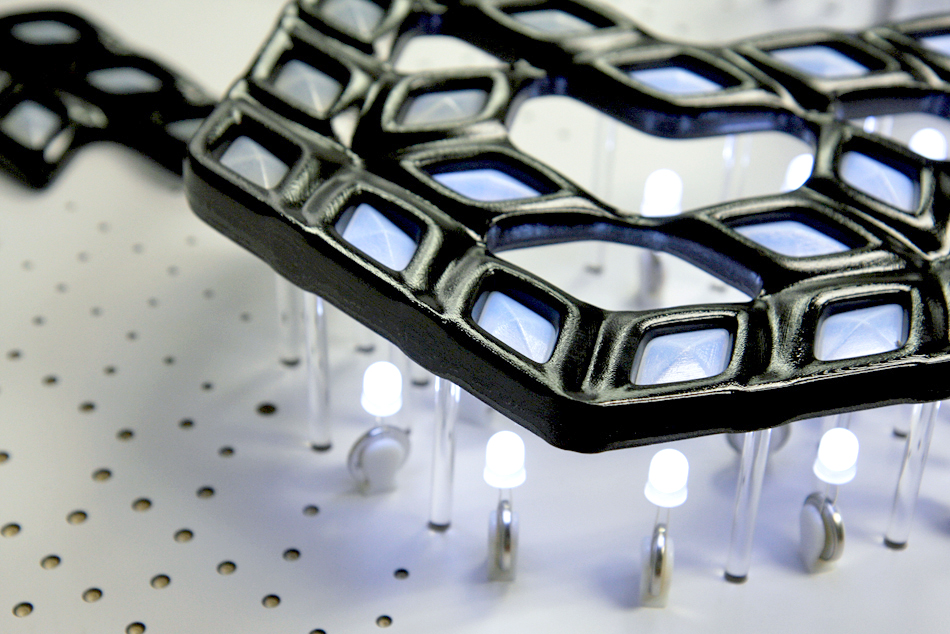

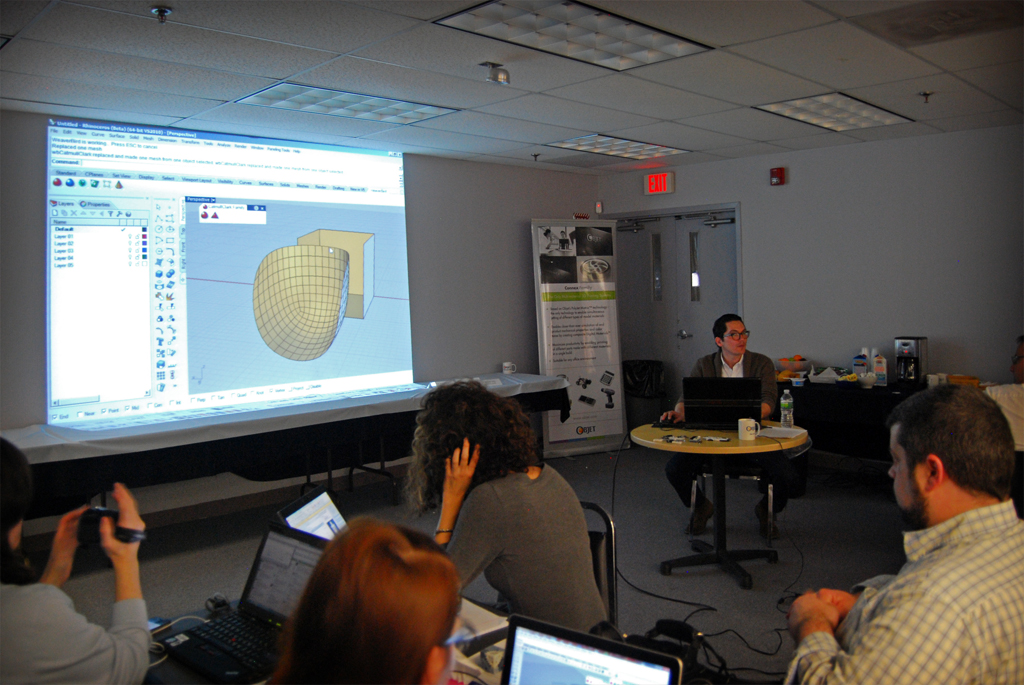

In addition to some amazing articles written by Daniel Davis, David Rutten, Daniel Piker, Giulio Piacentino, Arthur van der Harten, Thomas Grabner and Ursula Frick, and many more... it also features an article that I co-authored with Jason K. Johnson titled Firefly: Interactive Prototypes for Architectural Design.

In addition, make sure you also take a look at the book Prototype! edited by Julian Adenauer and Jorg Petruschat which was published by Form+Zweck last summer (2012). Written by leading individuals at world renown design labs and research centers, this book offers a unique compilation of articles centered around the topic of advanced forms of prototyping. In my article, IDE vs. IPE: Toward and Interactive Prototyping Environment I discuss the need to shift toward a more visually oriented Interactive Prototyping Environment (IPE) which addresses the limitations found in the existing IDE paradigm and opens up creative new opportunties for artists and designers.